for enquiries

milton keynes

+44 (0) 1908 240300

dawson@dcpuk.com

milton keynes

+44 (0) 1908 240300

dawson@dcpuk.com

The Stella field comprises the Stella Andrew sandstone reservoir containing light oil and rich gas condensate and the Stella Ekofisk chalk reservoir containing a volatile oil. The Harrier field comprises the Harrier Ekofisk and the Harrier Tor chalk reservoirs, both containing gas condensate.

The Field Development Plan for Stella and Harrier was approved by UK Government in April 2012. The development involves the drilling of subsea wells tied back to the “FPF-1” floating production unit, with the export of processed hydrocarbons to nearby oil and gas transportation pipelines. In total, five wells are scheduled to be drilled on the Stella field and two on the Harrier field.

The Greater Stella Area will be developed in a manner that maximises initial liquids production and maintain the gas processing facilities of the “FPF-1” floating production unit on plateau.

Technip was awarded the contract in July 2012 for completion of the major subsea works that are to be conducted to deliver first hydrocarbons from the GSA. As part of the offshore pile driving operations, Dawson Contract Piling was to supply a complete spread with all associated equipment, airline supply to a double acting hydraulic impact hammer with a minimum impact energy of 120 kNm. This should include offshore support personnel to a Technip nominated vessel for the purposes of pile installation for 2 manifolds MDC, NDC.

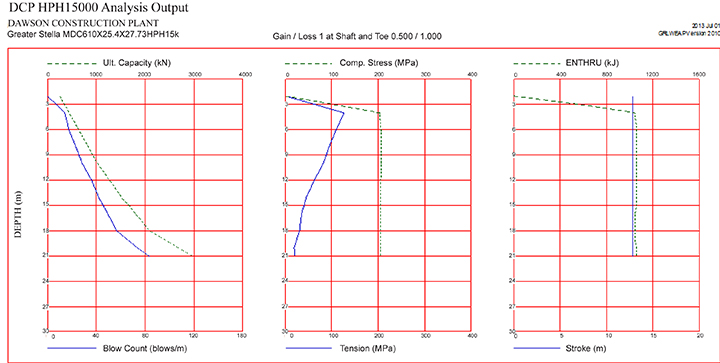

The MDC manifold structure was secured with four tubular piles of Ø24x1” and total length approximately 27.730m. The NDC manifold structure was secured in the same way with the piles being driven through the four corners of the manifold but with 24.03m length piles.

A Dawson Construction Plant 15k Hydraulic Impact Hammer was used to drive all 8 - Ø24 piles.

Piling commenced at the NDC Manifold at 08.25 on Sunday 28th July with all four piles driven into the spring lock system by 12.40. All piles were driven from start to finish on single blows with a gap of 10 seconds between each blow in line with soft start procedure.

With the hammer stored safely back on board the vessel move to the MDC manifold location and piling commence with the same procedure. The final pile was driven at 22.00 on Monday 29 July.

|

|

|---|---|

|

|